We may earn a small commission from any link to any products or services from this website. Your purchase helps support our work in bringing you real information about homesteading skills and preparedness.

Making Cold Processed Soap

When I told Tim I wanted to save our used cooking grease to make soap he just sort of looked at me. But he soon came to embrace my homemade soaps as a cheaper and more natural soap.

Cold processed soap is an easy method to make soap. There are a few safety precautions I will state upfront.

Safety:

Yes soap is made with lye. No lye, no soap. Lye is in drain cleaner and can be a powerful irritant on the skin. However, your stove can burn you but you still use it for cooking. Taking the right safety precautions can make soap fun and easy for the home soap-maker.

- Wear gloves. This is a non-negotiable part of making soap. You don't want lye on your skin, and gloves protect your hands.

- Wear safety glasses or goggles. You don't want lye on your skin or in your eyes. Pretty simple. Just wear it. Get them here.

- Keep pets and small children out of the work-space. Also seems obvious but unless they are also wearing gloves and safety glasses they should not be near the soap-making supplies.

- Good ventilation. When mixing the lye with water there will be gases released. This gas can give you a headache. Therefore, mix the lye outside or near a window. Mix it on your stove-top under the hood with the fan on, or have a fan in your window. Just keep the air moving so you don't gas yourself while attempting soap.

- Watch for burns. You will need to mix the fats while they are liquid, so if the fat is normally solid at room temperature you will need to heat it up. When mixing the lye with the water, it will create heat in an exothermic reaction. The container will get very (+150 F) hot, so make sure not to touch it.

- Avoid aluminum. Do not use aluminum utensils or bowls or molds. The lye will stain or effect the metals, rather use stainless steel bowls for mixing.

- Vinegar. Keep vinegar handy when dealing with the lye. If you do get lye on your skin, spray with vinegar. The vinegar will neutralize the lye. DO NOT RINSE the lye off. Remember that I said lye mixed with water gets very hot? That will happen on your skin too, try to get it mostly off before rinsing your skin.

- Watch the ratios. Making soap is chemistry, you need to make sure there is enough fat to react with every lye molecule. If you have too much lye then you will have extra lye left over and the soap will be really drying and may even burn your skin. If you have too much fat leftover, your soap will be very greasy, not what you want for soap. Depending on what you plan to use your soap for, will depend how much fat you want left-over. The fat will add moisture and make a nice lathering bar for skin, so you can super-fat your soap if you have dry skin. However if you plan to use your soap for dishes, then you don't want any left-over fats there. A soap calculator like this one will tell you how much lye to add depending what % fat you want left over.

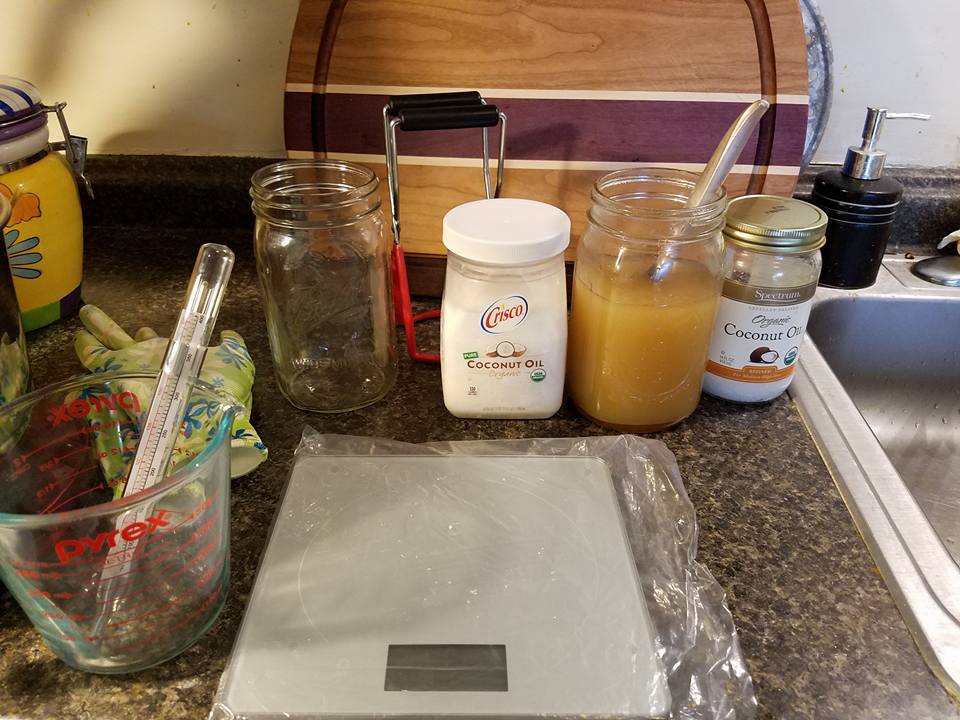

Tools:

Each tool mentioned, I link to the product I use. I recommend them because I use them and they work.

- Dedicated soap thermometer.

- Kitchen scale.

- Soap molds. (I use either old plastic containers or this bar mold)

- Glass or stainless steel mixing bowls.

- Safety gear: gloves, safety glasses, vinegar

- Immersion blender. The fats and lye need to be mixed very well. You can mix by hand (not recommended) but this will take a very long time. You could use a hand mixer or stand mixer but this also will take a bit of time. I highly recommend an immersion blender for this step. It will take you from 2 hours of mixing to 10 minutes!

Ingredients

- Fat: You can use almost any fat or oil you desire to make soap. These can be bought at your grocery store, specialty shops online or in bulk. You can also render your own fat from cooking or from cut fat from the butcher. See how I render my fat: 2 Ways to Render Fat for Soapmaking. This is a place where expensive oils can increase the price per bar of soap.

- Lye: I could link you to Amazon and make a commission when you buy Lye, but the cheapest Lye I have found is at BulkApothocary.com so go there, my conscious can't let you pay more than you should. Downsize there, is the minimum purchase is 8 lbs of Lye but at ~$2/lb.

- Water: Any household water will do.

- Optional: Fragrances, coloring, exfoliants. You can make a rose-colored, lavender smelling bar with coffee grounds to exfoliate your skin, if you like. I choose to keep my bars as cheap and raw as possible. These extras can increase the cost per bar greatly.

Steps:

- Calculate the amount of lye you need for your recipe. Yes recipes tell you exactly what you need, however it is good practice to check the amount of lye using a soap calculator. I use this website: Mountain Sage Soap Calculator. Making soap is chemistry, you need the proper ratio of ingredients to get a good soap. Determine how much fat you desire left-over after the reaction.

- Weight out your ingredients and melt your fats. Using your desired recipe and soap calculator, exactly weight out your ingredients. This is science people, don't be afraid but be precise as you can.

- In a ventilated space while wearing your safety glasses and gloves, combine solid lye and your liquid. Pour the lye into the water.

- Do not pour the water into the lye. Why bother? Well, as you pour the lye into the water the ratio if lye to water gets more and more concentrated.

- If you add the water to the lye, it is super concentrated to start with and is slowly diluted out. This may cause an explosive reaction of lye with the water. Don't do this!

- Pour the lye into the water.

- Stir well. Set aside and allow to cool (100° F to 125° F). This is where your thermometer is important.

- Measure and combine oils. Mix gently. Once the fats and oils are mixed and melted allow the temperature to drop to 100° F to 125° F.

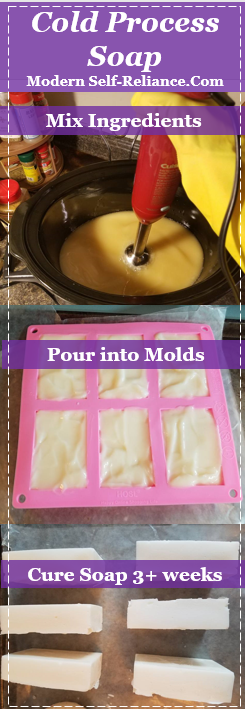

- Combine lye solution and melted oils. Be careful not to splash while combining the mixtures.

- Stir until the mixture reaches traces. Tracing looks like a slightly thickened custard, not instant pudding but a cooked custard. It will support a drop, or your stir marks for several seconds. If tracing takes more than 15 minutes, which it often does, stir for the first 15 minutes, then stir for 5 minutes at 15 minute intervals.

- If you plan to add colors, fragrances or others items. This is the point you would add the extras.

- Pour raw soap into your prepared molds. After a day, the soap can be turned out of the mold. If the soap is very soft, allow it to cure for a few days to firm the outside.

- Cut soap into bars when you take them out of the molds. At this point, a day later, your soap will be soft like fudge and should be easy to cut.

- Set the bars out to cure and dry for three or more weeks. This will allow the bar to firm and finish saponification (the chemical reaction). Place the bars on something that will allow them to breathe. After this period, the soap will be much harder and ready for use.

Tallow/Lard Soap:

Soap is a chemical reaction between water, fat and lye. It can be just that simple to make, three ingredients. For this recipe, I will be making the most basic soap you can make. My Tallow soap uses rendered beef fat, water and lye. I find this soap is good for cleaning dishes but too drying on my skin.

Ingredients:

- 1 lb (16 oz) lard/tallow (I have found for as low at $0.70/ lb or $0.09/oz)

- 2.09 oz lye ($2/lb or $0.13/oz)

- 4-6 fl oz of water (free)

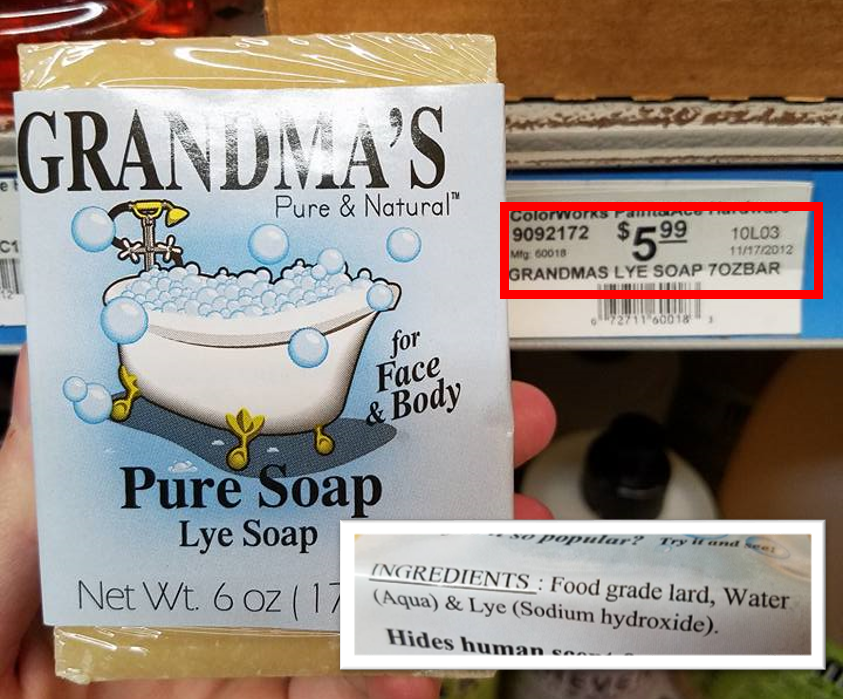

This recipe yields approximately 7 bars of 2-3 oz soap. It cost me roughly $0.14 cents per bar. So when I say this soap is cheap I mean cheap! One day, I was in the hardware store looking for canning jars, and right next to them was Grandma's Lye Soap for $6 a bar! Ingredients: lard, lye, water. Crazy expensive compared to what I can make at home!

Coconut-Tallow Soap:

For my skin I blend coconut oil into the soap to increase lather and moisturizing properties. I have been using this soap for six months now with no problems. No dry skin or greasy skin. Also no acne outbreaks like I was getting with the tallow soap above. This recipe is 1/3 coconut oil and 2/3 tallow.

Ingredients:

- 16 oz lard/tallow ($0.09/oz)

- 8 oz Coconut oil ($0.47/oz at $6.4/lb)

- 3.47 oz lye ($2/lb)

- 6-8 fl oz of water (free)

This recipes makes approximately 9-10 bars of 2-3 oz each. The costs come out to approximately $0.59 per bar. This is much more expensive than the tallow soap but cheaper than some store bought soaps. We use about 1 bar of soap per person per month for our body soap.

Conclusion

I hope I have convinced you that soap isn't a scary process and that you too can make soap at home. I learned off the internet from articles like this and The Soap Queen. I now make large batches about once every two months when I have saved enough excess fat and make 15-20 bars at a time. So this means every 2-3 months I make enough soap for 1 person for the year. Not bad for an afternoon's work.

I hope you enjoy making soap like I do, and experiment to find the best recipes for your skin. I think our bodies are unique, and what works for my skin may not be the best for your skin. I don't think there is a one-type fits all soap. But with homemade small-batch soap you can experiment with what works well for your family.

Ask any questions below!

2 Ways to Render Fat for Soapmaking

- Fitness: Working Out as Physical Preparedness - February 22, 2021

- Backpacking or 72hr bag meals - December 23, 2020

- 8 Security Concerns for a New Home - October 28, 2019

Thank you. I have been wanting to make soap for a long time. This information is the best I have found.

Glad to hear it! Let us know how your soap comes out.